Efficient purchasing also means having inventory control. Businesses need to know what they have in stock and what they don’t in order to make the right decisions when it comes to procurement. While you may already have a system in place and know which items need to be replaced and when, it can be difficult to determine whether your purchasing function is as effective as it can be.

By improving your purchasing function, you can expect significant cost savings. Ordering the correct amount of products that you need to keep your business running reduces any maverick spend on items you don’t need.

Goals of Inventory Management

An inventory management strategy aims to:

Prevent Dead Stock

When you run out of stock of an in-demand item, you’ll end up losing money and valuable customers. However, overstocking can also cost you money because it takes up floor space and can result in waste if the items do not sell in time. If you lease warehouse space, this can be extremely detrimental. You’ll want to minimize dead stock storage to make room for items that will sell to keep your costs lower.

Improve Organization

Effective inventory management requires a certain level of organization, which includes real-time tracking. You need to know where every item is located, how fast it’s used or moves, and what quantity you have in stock.

This will enable faster order fulfillment and reduce the risk of you having to tell valuable customers that the item they ordered is not in stock. Tracking these items will help you see which inventory you have and which you don’t so that you can determine what items need to be purchased and when.

Improve Reordering

Inventory management also means ordering the correct amount of stock you need and moving it as quickly as possible. When an item is sold, it should be taken out of stock automatically. When in-stock items reach a certain limit, the item should be automatically triggered for reorder, whether it has to be approved or not will be up to your business practices.

Positively Impact Budgeting

By effectively managing your inventory, you can better manage your cash flow. Keeping the right amount of goods in stock is key to your success.

Inventory Management Techniques

Your business requires a strategic inventory management process that saves time, boosts productivity, and helps keep your business a success. Check out these tips and techniques for an effective purchasing and inventory control system.

Invest in Software

If you want an effective purchase order system, which includes inventory management, you will probably need help as your business expands. Technology is crucial to businesses who have to manage a lot of items, suppliers, and budgets.

Purchase order management software uses automation to minimize data entry and update systems in real-time. This means that everyone involved in the PO process will be able to see what’s in stock at any given moment, and the database is then updated each time a product is sold or used.

Cloud-based purchasing software creates and stores tons of data to provide your business with the information you need to make informed purchasing decisions. You can view which items go out of stock most frequently and when you need to reorder them. You can also view the products that aren’t moving as much as you thought they were and change the policy on how often those items are reordered.

Remember, that the longer an item sits in your warehouse, the more it costs your business. Make sure that you use the data to make sure that your procurement process is as efficient and effective as it can be.

Predictive Analysis

Be as proactive as you can be. Use past purchase information to understand buying items for certain items and categories. Make sure you look at the data regularly because using insights in a strategic way can help boost sales and save your company money.

Predicting demand will be critical to your inventory management function. Use the data from the procurement software to find market trends and analyze previous sales. Next, you can examine season trends and any marketing efforts to ensure that you have enough product for an expensive spike in sales.

You can’t account for all variables that will affect your purchasing and inventory functions. However, you can plan for the future of your business and determine how to proceed using real-time data.

Centralized Ordering

Ordering through a purchasing office gives you control over incoming goods. Centralized ordering gives you dedicated experts trained to negotiate for the best deals. Purchasing managers will negotiate the best quality for the lowest price to keep your business running smoothly.

Suppliers typically require a minimum quantity to balance their costs. However, purchasing managers can work with suppliers to lower costs and spread delivery over a certain time period to avoid overstock costs.

Always Have a Back-Up Plan

For your procurement system to run smoothly, every step of the process will have to work properly. There are some inventory factors that you have no control over, though, such as raw materials and weather.

Your supply chain will invariably hit a snag, which can affect your entire company, including its customers. In order to mitigate risk, you’ll have to have a back-up plan for when things just don’t go according to plan.

While you can’t plan for everything, you can make your process a little more flexible to minimize any negative impacts on your business. Your back up plan might include local suppliers who can deliver quickly when there is an impending storm, and you don’t know when you’ll get products from another supplier.

A good back up plan involves communicating with your suppliers and building good relationships with them. If you maintain beneficial relationships, your suppliers may even give you a heads up when there may be a shortage so that you can plan accordingly.

Audit Regularly

Good inventory management and purchase order software will provide you with all the information you need. However, humans involved in the process can still make mistakes. For this reason, it’s important to make sure that the stock matches your reports.

You should still do a physical inventory once a year, but even that may not be enough. If the count doesn’t match the numbers, it can be complicated to find out what happened. To prevent this from happening, consider spot-checking your inventory every so often. You can pick a few of the items that move the fastest and count them to find any discrepancies.

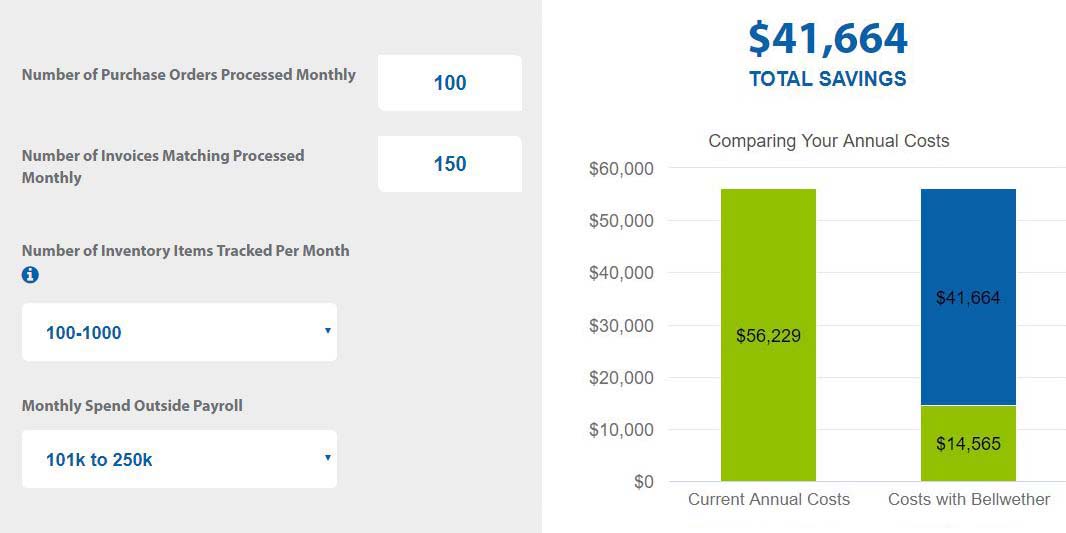

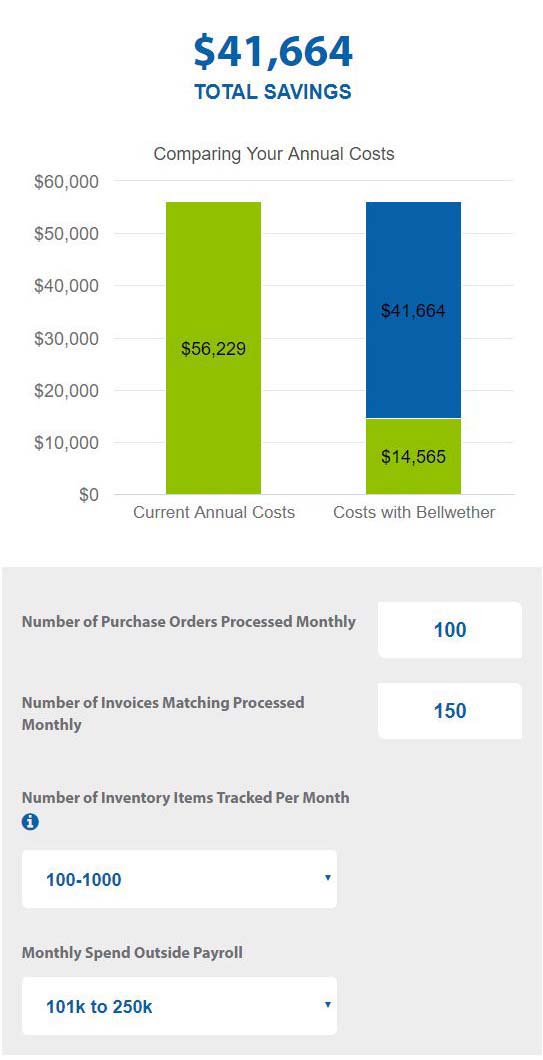

FREE ROI Report – just add your numbers!

%CODE1%